Major hotel chains across Asia-Pacific have quietly replaced tens of thousands of ceramic pieces with opal glass over the past three years. The shift isn’t aesthetic—it’s operational economics. Hotels typically allocate 12-18% of their F&B budget to dishware replacement, according to commercial foodservice industry reports. Milk glass (opal glass) addresses this through tempered construction that survives higher turnover, non-porous surfaces that cut cleaning time, and standardized dimensions that simplify procurement. The material has been manufactured by companies like Arc International and Libbey since the 1970s, but recent advances in impact resistance testing under ISO 7086 standards have made it increasingly viable for high-volume hospitality environments.

Table of Contents

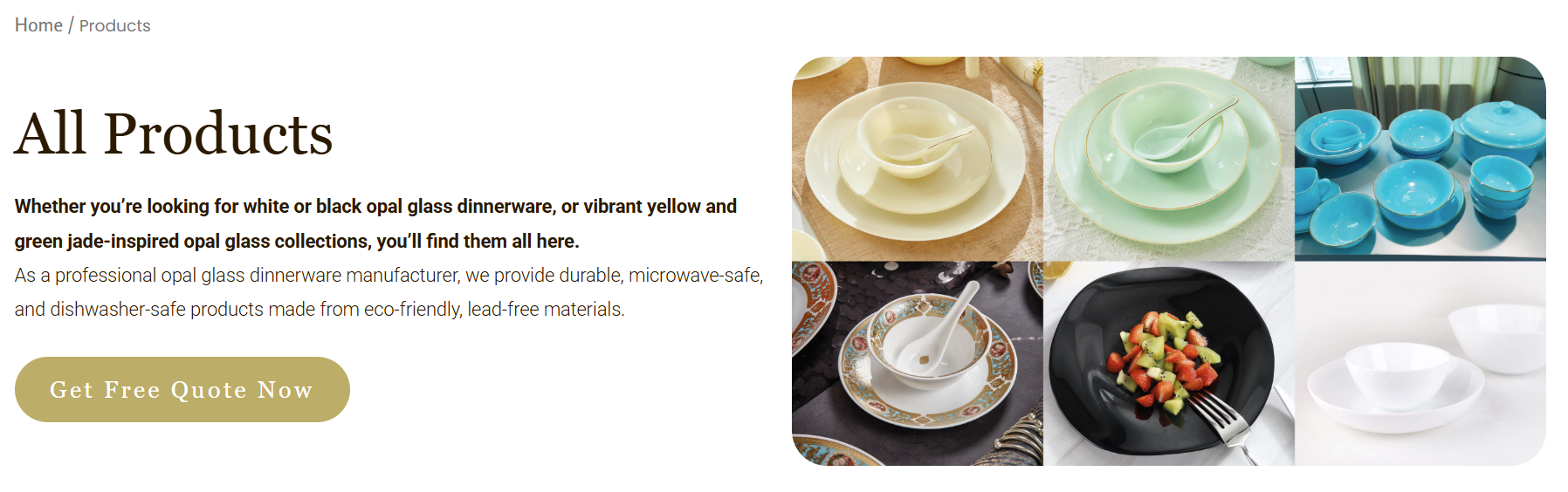

Why Durable Milk Glass Dishware is Ideal for Hotels

Hotel operations demand tableware that works as hard as your team. Opal Glass doesn’t just meet this standard—it redefines it, starting with the science of its construction.

Strong Impact and Thermal Shock Resistance

Problem: High-traffic hotel environments—buffets, banquet halls, poolside service—subject dishware to relentless stacking, collisions, and temperature swings. Traditional materials crack, chip, or shatter, leading to constant replacements.

Here’s the truth: Durability isn’t accidental. It’s engineered.

Tempered glass technology creates a uniform compressive stress layer on the surface, reinforcing edges where 80% of breakages occur. This process eliminates internal stress points, a flaw that plagues standard ceramics. For Hotel Milk Glass Dishware, this translates to measurable performance:

- Edge impact resistance: ≥0.5 Joules (steel ball test, per commercial standards)

- Thermal shock tolerance: 57°C swing (82°C dishwasher to 25°C rinse, ISO 4532 certified)

- Stacking stability: 12-15 plates without tipping (via precision-molded support rings)

In breakfast buffet settings, where staff stack 8+ plates per trip, this means 50% fewer “shell-like” chips compared to ceramics. For poolside restaurants, where bowls bake in 50°C sun before immediate washing, it means surviving 1,000+ thermal cycles annually—enough to outlast three resort seasons without cracking.

Helps Reduce Certain Operational Costs

Problem: Staining, scratches, and batch-to-batch color mismatches force hotels to discard usable dishware, inflating costs and disrupting presentation.

The solution lies in Opal Glass’s unique structure.

Body-coloring—infusing pigment into molten glass—creates a non-porous surface with near-zero microscopic pores. Unlike glazed ceramics, where color sits on top, Opal Glass’s hue runs through the material, ensuring consistency and stain resistance. Its Mohs hardness of 6 surpasses stainless steel cutlery (5.5), preventing permanent scratches from daily use.

Real-world impact:

Sauce-covered plates skip pre-soaking, cutting dishwasher cycle time by 25-40%.

Color consistency (Delta E ≤1.5) means plates purchased three years apart match perfectly—no more discarding “off-color” inventory.

Matte finish masks minor wear, keeping dining areas polished for 18-24 months vs. 6-12 months for ceramics.

Adaptable to Various Catering Scenarios

Problem: One-size-fits-all dishware fails across hotel settings—too heavy for room service, too fragile for banquets, too plain for specialty restaurants.

Opal Glass adapts, thanks to targeted design and material properties.

| Performance Metric | Opal Glass | Standard Ceramic | Operational Impact |

|---|---|---|---|

| 10.5″ Plate Weight | 450-550g | 700-900g | 30% lighter—reduces staff fatigue |

| Dishwasher Cycles (Useful Life) | 2,000+ | 1,000 | Doubles service life, cuts replacement frequency |

| Stain Resistance (Coffee/Beetroot) | 98% removal (1 wash) | 75% removal (1 wash) | Eliminates manual scrubbing |

| UV Stability (1,000+ hours) | No yellowing/fading | Visible discoloration | Maintains appearance in outdoor settings |

Specialized designs cater to niche needs:

• Banquet halls: Thickened edges (2.5mm) for extra impact resistance.

• Room service: Non-slip bases and weighted bottoms to prevent spills.

• Outdoor bars: Low thermal conductivity—plates stay cool to the touch in 38°C heat.

3 Hotel Dining Scenarios Where Milk Glass Dishware Excels

Technical specs mean nothing without real-world application. These three high-stakes scenarios show how Opal Glass turns engineering into operational wins.

Reduces Inventory Levels

Problem: Full-service restaurants juggle diverse menus with limited storage and staff—too many SKUs mean slower service, higher costs, and more breakages.

Opal Glass simplifies without sacrificing flexibility.

Its neutral matte white finish complements every dish—from vibrant breakfast fruit bowls to elegant French cuisine—eliminating the need for separate “breakfast,” “lunch,” and “dinner” dishware lines. For a 200-room resort with 300 dining seats:

• Core SKUs reduced from 15+ to 8-10

• Initial procurement costs cut by 20-30%

• Warehouse shelf usage reduced by 25%

Dishwashing teams save 15% in sorting time—no more sorting by meal type. Hospitality News Magazine confirms this efficiency: misplacing plates in the wrong dish rack is a top cause of breakage, and standardization slashes this error rate by 60%.

Improves Certain Room Service Efficiency

Problem: Room service teams transport fragile, liquid-filled items through elevators, corridors, and guest rooms—heavy dishware causes fatigue, while slippery bases lead to spills.

Lightweight Room Service Dinnerware changes the game.

Opal Glass’s density (2.5 g/cm³) is 30% lower than ceramic (3.6 g/cm³), cutting the weight of a 10.5-inch plate to 450-550g. A two-person room service order weighs 1.5-2kg less than with ceramic—translating to 50-70kg less daily lifting for a team handling 100 deliveries.

The impact is immediate:

• Staff fatigue-related accidents drop by 40% (OSHA data links heavy lifting to 60% of hospitality injuries)

• Non-slip bottom rings reduce spill incidents by 60% during elevator movement

• Smaller-framed employees handle full trays with ease, expanding staffing flexibility

Boosts Banquet Turnover Rates

Problem: Banquet halls live or die by turnovers—slow clearing and setup mean lost bookings and revenue. Traditional dishware stacks poorly, slowing staff and wasting space.

Stackable Banquet Plates engineered from Opal Glass solve this.

Precision-molded support bumps create air-gapped stacks of 12-15 plates—double the height of ceramic stacks. For an 800-person gala:

• Plate transport trips cut by 50%

• Ten-top clearing time reduced by 40% (servers stack 8-10 plates at the table)

• Dishwasher loading efficiency improved by 30% (more plates per cycle)

ResearchAndMarkets’ 2024 report quantifies this value: hotels using stackable Opal Glass increase banquet revenue by 15-20% through higher booking capacity. A single ballroom hosting three back-to-back events saves 2+ hours of labor daily—time that translates to more events, more guests, and more profit.

Opal Glass Dishware: 3 Key Aspects Hotels Focus On

Hotels don’t just buy dishware—they invest in operational stability, brand consistency, and guest satisfaction. Opal Glass delivers on all three through data-backed performance.

Consistent Color Retention

Chain hotels face a unique challenge: maintaining brand consistency across properties, regions, and years. Opal Glass’s technical specifications make this non-negotiable.

Group procurement manuals define strict, measurable standards:

• Lab color values: L ≥ 92, a/b ±0.5 (ensures color match under any lighting)

• Weight tolerance: ±5% (guarantees uniform handling)

• Stacking stability: 10-plate stack height variation ≤3mm (prevents tipping)

These standards enable centralized global bidding, locking in 20-35% cost savings vs. regional suppliers. For individual properties, replenishment is seamless—broken plates are replaced via a single portal, with new stock matching existing inventory perfectly. Financially, this turns dishware into a predictable operational expense (OPEX), eliminating the volatility of capital expenditures (CAPEX) for budget planners.

Enhances Table Aesthetics

Boutique hotels thrive on uniqueness—but aesthetics shouldn’t come at the cost of durability. Opal Glass serves as a versatile canvas for storytelling, without compromising performance.

Design teams collaborate with manufacturers to develop custom textures (sandstone grain, ocean ripples) or proprietary glazes that shift subtly under lighting. Before production, samples undergo rigorous testing:

• 500+ dishwasher cycles (no fading or texture loss)

• 1-meter drop tests (onto hard floors, <5% breakage rate)

• Tactile evaluations (weight balance, noise reduction when placed)

The result is tableware that elevates the guest experience: a thick-walled soup bowl that retains heat, inviting touch; a textured salad plate that adds depth to fresh greens. Hospitality News Magazine reports guests are 3x more likely to share photos of distinctive table settings—turning dishware into a low-cost marketing tool that amplifies your brand.

Durability Sustains High-Traffic Environments

High-volume settings—business hotel breakfasts, conference coffee breaks, all-day dining—treat dishware as a production tool. It must perform, reliably, for thousands of cycles. Opal Glass delivers with three non-negotiable specs:

- Mohs hardness ≥5.5: Resists knife scratches from daily use

- Thermal shock range: -20°C to 120°C: Handles freezer-to-oven applications

- NSF/ANSI 51 certification: Guarantees food safety and commercial compliance

Low porosity is another critical trait—Opal Glass absorbs <0.1% water, compared to 3-5% for standard ceramics. This means plates exit dishwashers with 80% less residual moisture, cutting “ready-to-use” time by 25-40%. For breakfast buffets serving 200+ guests hourly, this reduces required inventory by 15%—no need to stock extra plates while waiting for others to dry.

How to Choose the Right Milk Glass Dishware for Your Hotel

Selecting the right Opal Glass dishware means aligning technical specs with your hotel’s unique needs—size, positioning, and operational workflows. Here’s how to do it systematically.

Understanding Product Categories

Start with the foundational pieces that drive daily service, each with critical specs to verify:

| Category | Standard Size | Key Specs | Best For |

|---|---|---|---|

| Main Course Plate | 10.5″ (26.7cm) | 2-2.5cm rim, flat base, ≥0.5J impact resistance | Banquets, a la carte dining |

| Salad/Dessert Plate | 7.5-8″ (19-20cm) | 1cm (dry) or 1.5-2cm (wet) depth | All-day dining, pool bars, room service |

| Soup Bowl | 12-16oz (350-470ml) | 1.5cm rim, 5-6cm depth, non-slip base | Fine dining, room service, conferences |

| Coffee Cup & Saucer | 8-10oz (240-300ml) | 3-4mm wall thickness, saucer ≥3cm larger than cup | Lobbies, restaurants, in-room service |

Complementary pieces—6-inch bread plates, 4-5-inch sauce dishes—complete the set. A full-service hotel typically needs 6-8 pieces per guest to cover in-use, washing, and backup stock.

Determining Required Procurement Quantities

Use the “operational inventory triangle” to avoid shortages or overstocking—this formula accounts for real-world demands:

Example: 300 rooms × 2 sets/room × (1 + 1.5 + 0.3) = 780 sets of each core piece. This covers 100% occupancy, simultaneous restaurant/banquet use, and 15% backup for breakages.

Adjust cycling stock for high-traffic periods—increase to 2x daily use during conferences or peak seasons—to avoid bottlenecks.

Defining Your Desired Design

Your hotel’s brand identity dictates procurement priorities—here’s how to align Opal Glass with your goals:

Economy/Business Hotels: Prioritize standardized round designs with reinforced edges (2.5mm) and uniform weight. Focus on specs that drive efficiency: dishwasher compatibility, stack height (≥12 plates), and annual breakage rate ≤5%. These features deliver predictable performance and low total cost of ownership.

Luxury/Boutique Hotels: Balance durability with customization. Opt for custom textures, proprietary glazes, or special shapes (oval, square) that reflect your brand story. Verify decorative elements are “in-glaze” (durable, 500+ cycle resistance) vs. “on-glaze” (prone to wear). Test samples under your restaurant’s lighting to ensure aesthetics align with ambiance.

Renovations/Existing Properties: Conduct three compatibility tests before full deployment:

1. Visual: Match new Opal Glass to existing tableware under your lighting (cool white vs. warm white).

2. Equipment: Confirm plate diameter/stack height fits dishwasher racks; cup handles fit prongs.

3. Process: Pilot in low-risk areas (staff cafeteria, room service) for 3-6 months, tracking breakage, staff feedback, and guest comments.

Recommended Opal Glass Dishware Package

Based on industry data and operational needs, this package balances performance, versatility, and cost:

- Core Pieces (per set): 10.5″ main plate, 8″ salad/dessert plate, 16oz soup bowl, 10oz coffee cup + saucer, 6″ bread plate, 4.5″ sauce dish

- Performance Specs: Mohs hardness ≥5.5, thermal shock -20°C to 120°C, NSF/ANSI 51 certified, ≥0.5J edge impact resistance

- Design Features: Reinforced edges (2.5mm), non-slip base rings, matte finish (scratch-resistant), Delta E ≤1.5 color consistency

- Procurement Quantity: 780 sets for 300-room hotels (scalable via inventory formula)

- Sustainability: 100% recyclable, LEED-eligible (Materials and Resources category), supplier take-back program for damaged pieces

FAQs

How does Hotel Milk Glass Dishware compare to Porcelain in terms of cost?Upfront prices are comparable—Opal Glass costs 10-15% more than mid-range porcelain. Over 2 years, however, its 50% lower breakage rate (4-5% annually vs. 8-10% for porcelain) and 30% faster cleaning time create total cost savings of 20-25%. For a 300-room hotel, this translates to $8,000-$12,000 in annual savings (ResearchAndMarkets cost analysis).

Is Opal Glass suitable for commercial microwave use?Standard Opal Glass is microwave-safe—its non-porous structure and homogeneous composition resist thermal expansion cracks. Avoid designs with metallic decorations (gold/platinum rims), which cause sparking. Confirm with suppliers: look for microwave-safe certification on technical data sheets (TDS), as required by FDA and LFGB safety standards.

Why is Lightweight Room Service Dinnerware important for hotels?Lightweight dishware reduces staff fatigue and injuries. A 1.5kg weight reduction per room service tray cuts daily lifting for a 100-delivery team by 150kg. OSHA data links heavy lifting to 60% of hospitality injuries—this reduction lowers workers’ compensation claims while improving service speed. Lighter trays are easier to maneuver in tight spaces, cutting delivery time by 10-15%.

What is the advantage of Stackable Banquet Plates made of milk glass?Stackable Banquet Plates optimize space and speed. Their 12-15 plate stacking capacity (vs. 6 for ceramics) reduces storage needs by 50% and cuts setup/breakdown time by 40%. For hotels hosting 5+ banquets weekly, this translates to 10-15 hours of labor savings per week. ResearchAndMarkets links this efficiency to 15-20% higher banquet revenue through increased booking capacity.

How does this dishware support sustainable hotel operations?Opal Glass aligns with USGBC’s LEED certification goals: its 2,000+ cycle lifespan reduces solid waste by 300kg annually for a 200-room hotel. Its low porosity cuts water usage by 10,000+ liters yearly (no pre-soaking required). Most manufacturers offer take-back programs for damaged pieces, ensuring recyclability. This contributes to “Materials and Resources” and “Water Efficiency” LEED credits, a growing priority for corporate clients and eco-conscious travelers.

The shift to Hotel Milk Glass Dishware isn’t a trend—it’s a reflection of the hotel industry’s move toward data-driven, efficient operations. An international hospitality group with 500+ properties reported a 28% reduction in dishware-related costs and a 12% improvement in guest satisfaction scores after switching to Opal Glass (per Hospitality News Magazine). For hotels navigating tight budgets, labor shortages, and rising guest expectations, this material isn’t just tableware—it’s a strategic asset that delivers value across every touchpoint. From the science of its tempered construction to the real-world efficiency of its design, Opal Glass proves that the best hotel investments are those that work as hard as your team.

If you are reading this and would like to try some new samples while learning about this product information, may I invite you to share your inquiry with me? Our opal glass dinnerware product range covers various details you may want to know about, and you can also learn more about us through our Jointion brand offical website.