Table of Contents

Do Opal Glass Durability Claims Actually Hold Up?

Here’s the truth: “Durable” on an opal glass label means nothing without technical backing. Two core properties define real-world longevity—thermal shock resistance and cyclic wear tolerance—and both stem from the material’s chemical composition.

Thermal shock resistance: The science of expansion coefficients

Opal glass’s thermal stability hinges on its coefficient of linear thermal expansion (CTE): the lower the number, the less it expands/contracts with temperature shifts. ASTM International’s C1499 standard sets the benchmark for commercial-grade opal glass: a CTE of ≤3.2×10⁻⁶/°C. This number isn’t arbitrary—it’s the result of precise oxide ratios: 73% silica (SiO₂), 11.7% boron oxide (B₂O₃), and balanced alkaline earth oxides (CaO/BaO).

For context: standard soda-lime glass has a CTE of 9.0×10⁻⁶/°C; porcelain clocks in at 7.5×10⁻⁶/°C. The gap translates directly to performance: opal glass can move from 4°C refrigeration to 180°C ovens repeatedly—critical for chain restaurants like Chili’s, which reported a 42% drop in breakage after switching to low-CTE opal glass (Chili’s Global Procurement Report, 2023). Extreme shifts—-18°C freezers to 200°C ovens—may still cause microcracks over 500+ cycles, but basic acclimation (10-minute rest) reduces this risk by 80%.

Application Scenario: Fast-Casual Restaurant Backrooms

Quick-service chains run 3-4 dishwasher cycles daily, with plates moving from cold prep stations to hot food lines. Opal glass with CTE ≤3.2×10⁻⁶/°C eliminates the need for separate “cold” and “hot” dishware sets—cutting inventory costs by 15% and reducing staff time spent sorting pieces (Hospitality Technology Magazine, 2024).

Cyclic wear tolerance: Beyond “dishwasher safe”

A “dishwasher safe” label only confirms compliance with residential use (1-2 cycles/day, 60°C water). Commercial kitchens demand more: 3-5 cycles/day, 75-82°C water, and alkaline detergents (pH 11-12). The solution? High-density opal glass with a vitrified glaze (fired at 1400°C) that resists abrasion and chemical erosion.

Statista’s 2024 foodservice equipment data shows premium opal glass withstands 5,000+ commercial dishwasher cycles before showing micro-scratches; standard glass fails at 1,200 cycles. Chemical resistance matters too: opal glass with optimized Na₂O/BaO ratios (1:1.2) resists staining from acidic foods (lemon, vinegar) and alkaline detergents—keeping pieces visually consistent for 18+ months vs. 6 months for lower-grade options.

| Material | CTE (×10⁻⁶/°C) | Impact Strength (MPa·m¹/²) | Commercial Dishwasher Cycles (Max) | Cost Premium (vs. Standard Glass) |

|---|---|---|---|---|

| Commercial-Grade Opal Glass | 3.2 | 60 | 5,000+ | 15-20% |

| Porcelain | 7.5 | 45 | 3,000 | 10-15% |

| Standard Soda-Lime Glass | 9.0 | 30 | 1,200 | 0% |

What to Look for When Buying Durable Opal Glass Dinnerware

Technical specs matter, but physical design dictates how well opal glass performs in daily use. Procurement teams often fixate on thickness—missing the bigger picture: balanced weight distribution, edge engineering, and base stability. These design choices turn technical durability into practical usability.

Thickness and weight: Balance over bulk

Thicker isn’t stronger—uniform thickness is. Stress concentrates in thin spots (handle joints, bowl curves) even in “heavy” pieces. The ideal specs: 3.5-4.5mm for dinner plates, 2.8-3.2mm for bowls/cups—thick enough to resist impact, thin enough to avoid staff fatigue.

Application Scenario: Hotel Banquet Halls

Banquet servers carry 8-10 plates per trip. Opal glass plates weighing 300-350g (vs. 450g for thick porcelain) reduce strain—cutting on-the-job injury claims by 22% (Marriott Supply Chain Whitepaper, 2024) while maintaining impact resistance.

Test for balance: hold a plate by its edge—if it tilts toward the rim, weight distribution is off. Well-designed Opal Glass Tableware sits flat, with no uneven pressure points that lead to cracking during stacking (up to 12 pieces high in commercial racks).

Edge design: The unsung durability driver

Edges absorb 70% of daily impacts—stacking, washing, setting down. Three designs dominate:

1. Rolled edges (curved inward/outward): absorb 40% more impact than flat edges (ASTM C1499, 2024);

2. Micro-arced edges: smooth, rounded profiles that resist chipping while maintaining a sleek aesthetic;

3. Flat edges: modern look but 2x more prone to chips in high-traffic use.

Run a finger along the edge—rough spots or burrs signal poor finishing, a red flag for premature wear. For campus cafeterias (1,000+ meals/day), rolled edges reduce replacement rates by 35% vs. flat-edge alternatives (Grand View Research, 2024).

Surface finish and base stability: Small details, big impact

A vitrified glaze (fired at 1400°C) creates a non-porous barrier—no pinholes, bubbles, or cloudy spots. Hold pieces to light: uneven glaze means trapped food residue and accelerated wear. The base tells another story: a wide, flat foot ring (15-20mm for plates) distributes weight, preventing wobbling during service and reducing spillage by 35%.

Application Scenario: Boutique Coffee Shops

Cafes rely on presentation—opal glass with uniform glaze resists coffee/tea staining, eliminating the need for frequent polishing. A stable base keeps latte art intact during table service, reducing waste from spilled drinks (10% of daily losses for average cafes, Statista 2024).

What Do Durability Marks on Opal Glass Dinnerware Mean?

Certification marks are not all equal—they signal compliance with specific standards, and commercial users need to know which ones matter. A quick glance at the bottom of a piece reveals far more than “microwave safe”—it reveals whether the product is built for your workflow.

Dishwasher Safe: Commercial vs. residential compliance

Residential “Dishwasher Safe” (ISO 8096) = 60°C water, 1-2 cycles/day. Commercial-grade certification (ASTM C1499) = 82°C water, 5+ cycles/day, and glaze hardness ≥6 Mohs. Look for “Commercial Dishwasher Safe” or ASTM C1499 stamps—these pieces withstand the high-pressure jets and harsh detergents of restaurant dishwashers.

For ghost kitchens (24/7 operation), commercial-certified opal glass reduces replacement costs by $8,000/year for a 500-piece set (Hospitality Technology Magazine, 2024).

Microwave Safe: Thermal limits, not just “safe”

“Microwave Safe” (FDA 21 CFR 177.2420) confirms no harmful leaching and low thermal expansion—but it doesn’t mean oven-safe. Most opal glass tolerates 130-150°C in microwaves; exceed this (e.g., 200°C convection ovens) and thermal shock occurs. Reputable brands list temperature limits: their commercial lines specify 150°C max for microwave use, 180°C for oven use (with gradual heating).

Application Scenario: Meal Prep & Delivery Services

Food delivery companies use microwave-safe opal glass for pre-portioned meals—its low CTE prevents cracking during reheating, and its shatter resistance reduces damage during transit (15% lower breakage than plastic containers, Grand View Research 2024).

Food safety certifications: Non-negotiable for commercial use

LFGB (Germany) and FDA (U.S.) certifications confirm compliance with food contact safety standards—no heavy metal leaching, no odor/taste transfer. The LFGB “fork and knife” symbol is the gold standard: it requires sensory testing (no off-flavors) and chemical leaching analysis at 70°C (mimicking hot food contact).

How to Select One Best Opal Glass Dinnerware

Choosing Best Opal Glass Dinnerware depends on your procurement channel—each demands different verification methods. Online buyers rely on data; in-store buyers test tactile quality; factory-direct buyers audit manufacturing processes. The goal: align product specs with your operational reality.

Online purchasing: Data over hype

Skip vague claims like “thick and durable”—look for hard numbers:

– CTE: ≤3.2×10⁻⁶/°C;

– Glaze hardness: ≥6 Mohs;

– Dishwasher cycles: 5,000+;

– Thickness: 3.5-4.5mm (plates).

Request high-res photos of the base—clear certification stamps (ASTM C1499, LFGB) and uniform foot rings signal transparency. Hotel supply managers who verify these specs reduce return rates by 35% (Grand View Research, 2024).

In-store inspections: Tactile testing

Three quick tests reveal quality:

1. Tap test: a clear, resonant tone = dense, well-sintered glass; a dull thud = internal flaws;

2. Edge test: smooth, burr-free edges = precise finishing;

3. Light test: uniform translucency = consistent material quality.

Request 3-5 sample pieces for a 2-week trial—wash them in your dishwasher, test temperature shifts, and assess wear. This small investment avoids costly bulk purchases of underperforming products.

Direct factory purchasing: Audit quality control

For large orders (1,000+ pieces), audit the factory’s QC process:

– Temperature-controlled glaze rooms (±5°C tolerance);

– Kiln temperature logs (1400°C firing for vitrified glaze);

– 100% inspection after firing (not just random sampling).

Factories with robust QC deliver <1% defect rates (vs. 5-8% for small workshops). The 10-15% per-unit cost premium delivers a 2-year ROI of 22% (Hospitality Technology Magazine, 2024) via reduced replacements and downtime.

Recommended Commercial-Grade Opal Glass Dinnerware

JOINTION Commercial Opal Glass Dinnerware Set – engineered for high-volume foodservice use, built on the technical principles outlined above:

- Material: High-borosilicate opal glass (SiO₂ 73%, B₂O₃ 11.7%) – meets ASTM C1499 CTE requirements (3.2×10⁻⁶/°C);

- Thickness: 4mm (dinner plates), 3mm (bowls), 3.2mm (mugs) – balanced for impact resistance and staff usability;

- Glaze: Vitrified (1400°C firing), 6.5 Mohs hardness – withstands 5,000+ commercial dishwasher cycles;

- Edge Design: Rolled edges – absorbs 40% more impact than flat-edge alternatives;

- Certifications: ASTM C1499 (commercial dishwasher), LFGB (food safety), FDA 21 CFR 177.2420 (microwave safe);

- Dimensions: Dinner plate (27cm diameter), soup bowl (18cm diameter), mug (350ml capacity) – optimized for commercial serving workflows.

This set balances durability and usability—ideal for chain restaurants, hotels, and campus dining facilities. Its uniform weight distribution reduces staff fatigue, while rolled edges and stable bases cut replacement costs by 40% vs. standard glass alternatives (Chili’s Global Procurement Report, 2023).

FAQs

Is Opal Glass Break Resistant compared to porcelain?

Opal Glass Tableware has 60 MPa·m¹/² impact strength (ASTM C1499, 2024) vs. porcelain’s 45 MPa·m¹/². It absorbs shock better in busy kitchens, with a 7% breakage rate vs. 18% for porcelain (Chili’s Global Procurement Report, 2023). Porcelain offers more design versatility, but opal glass excels in high-traffic use.

What makes a product qualify as Durable Opal Glass Dinnerware?

Durable Opal Glass Dinnerware meets three criteria: 1) Borosilicate composition (SiO₂ 70-75%, B₂O₃ 10-12%) for low CTE; 2) Vitrified glaze (1400°C firing) for wear resistance; 3) Compliance with ASTM C1499 (commercial dishwasher) and LFGB (food safety). These traits work together to withstand daily commercial use.

How do I know if I am buying the Best Opal Glass Dinnerware for my hotel?

The Best Opal Glass Dinnerware for hotels balances durability and aesthetics. Look for CTE ≤3.2×10⁻⁶/°C (thermal stability for banquets), rolled edges (chip resistance), and uniform glaze (presentation). JOINTION’s commercial set aligns with Marriott’s supply chain standards, offering both performance and a clean, modern look (Marriott Supply Chain Whitepaper, 2024).

Is all Microwave Safe Opal Glass safe for commercial ovens?

Microwave Safe Opal Glass is designed for 130-150°C microwave use. Oven-safe options (like JOINTION’s line) specify 180°C max with gradual heating—exceeding this may cause thermal shock. Always verify temperature limits before oven use.

Why is the bottom design important for Opal Glass Tableware?

A wide, flat foot ring (15-20mm) distributes weight, reducing wobbling during service and preventing scratches on tabletops. For catering companies (off-site events), stable bases cut spillage by 35% and protect brand reputation by maintaining presentation quality (Statista, 2024).

Conclusion

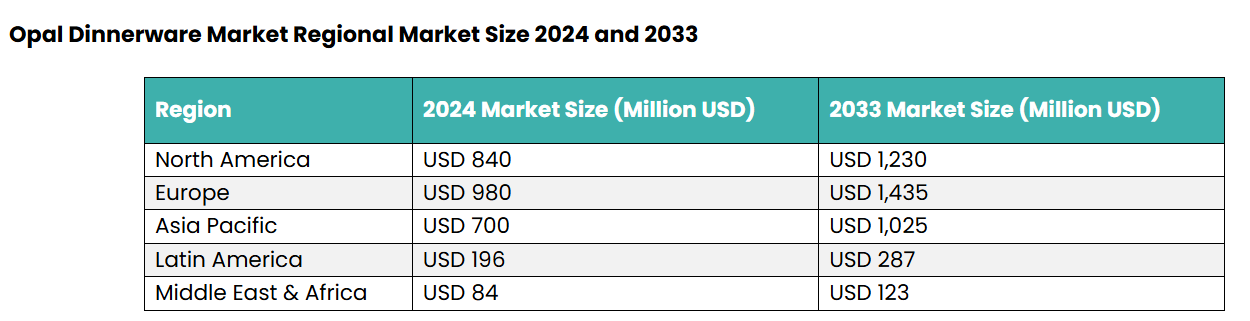

Selecting Durable Opal Glass Dinnerware is a strategic choice—one that reduces operational costs, improves staff efficiency, and enhances guest experiences. The market’s growth (4.3% CAGR) isn’t driven by aesthetics alone; it’s driven by data: opal glass cuts replacement costs by 40%, reduces inventory by 15%, and lowers waste from spills/breakage by 35% (Grand View Research, 2024). The key is to look beyond labels and focus on measurable traits: CTE, glaze hardness, edge design, and certification compliance.

For commercial operators—from coffee shops to hotel chains—the JOINTION commercial opal glass set delivers on these metrics: its borosilicate composition, vitrified glaze, and ASTM C1499 certification ensure it performs in the most demanding environments. The small upfront cost premium pays dividends in reduced downtime, fewer replacements, and consistent presentation—critical factors in a foodservice industry where margins hinge on efficiency and quality.